More photos to come soon!

We kicked off our T42 Wall Raising Build Blitz on Monday with T42 SIPs Prep. Tuesday and yesterday were wall raising days. On Tuesday morning my beloved landie Tony came with me to Sun Belt Rentals to pick up the scaffolding we're renting for the week. With our new truck loaded up, we headed to the job site (with a quick stop at the coffeeshop, of course!)

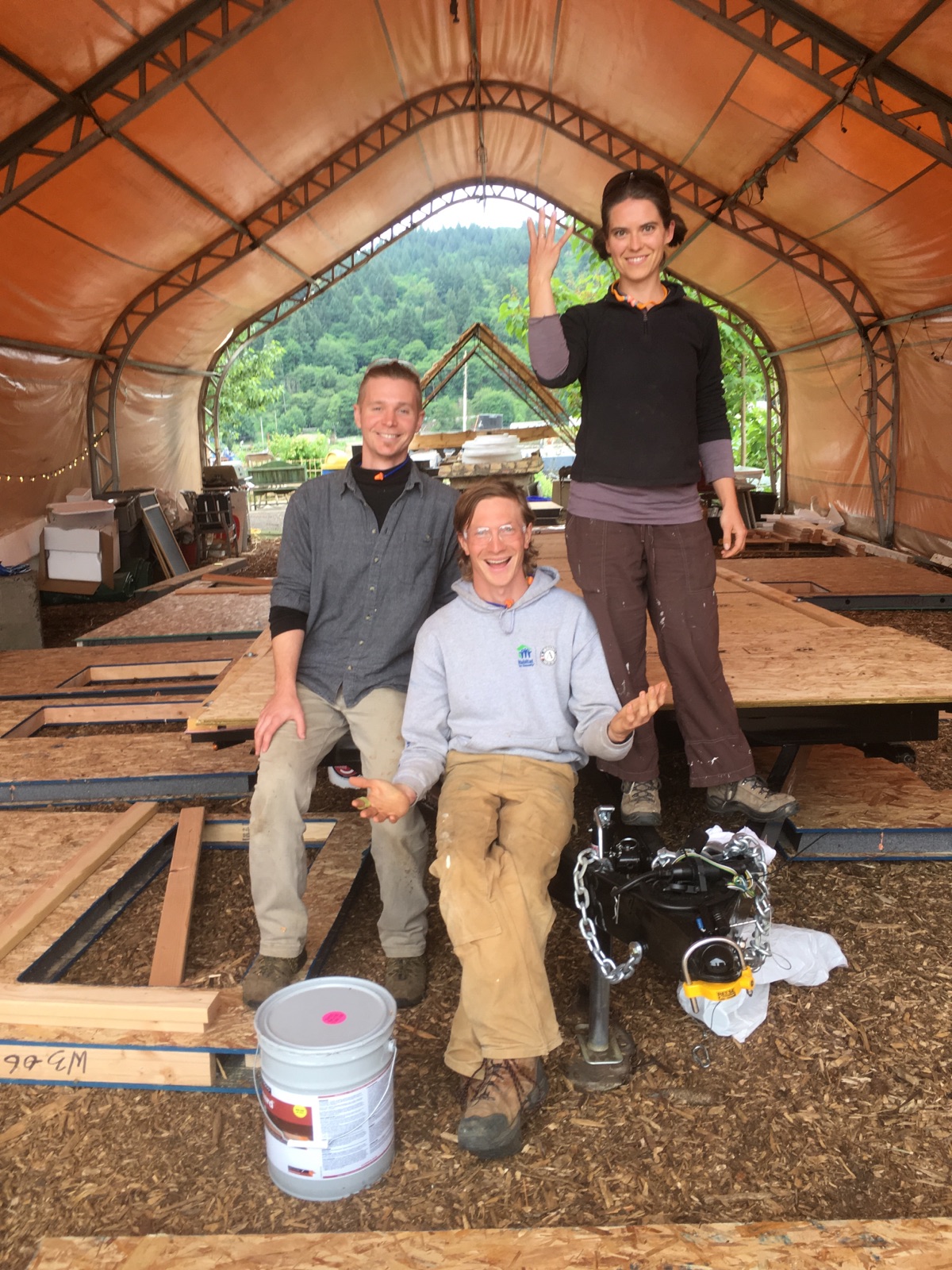

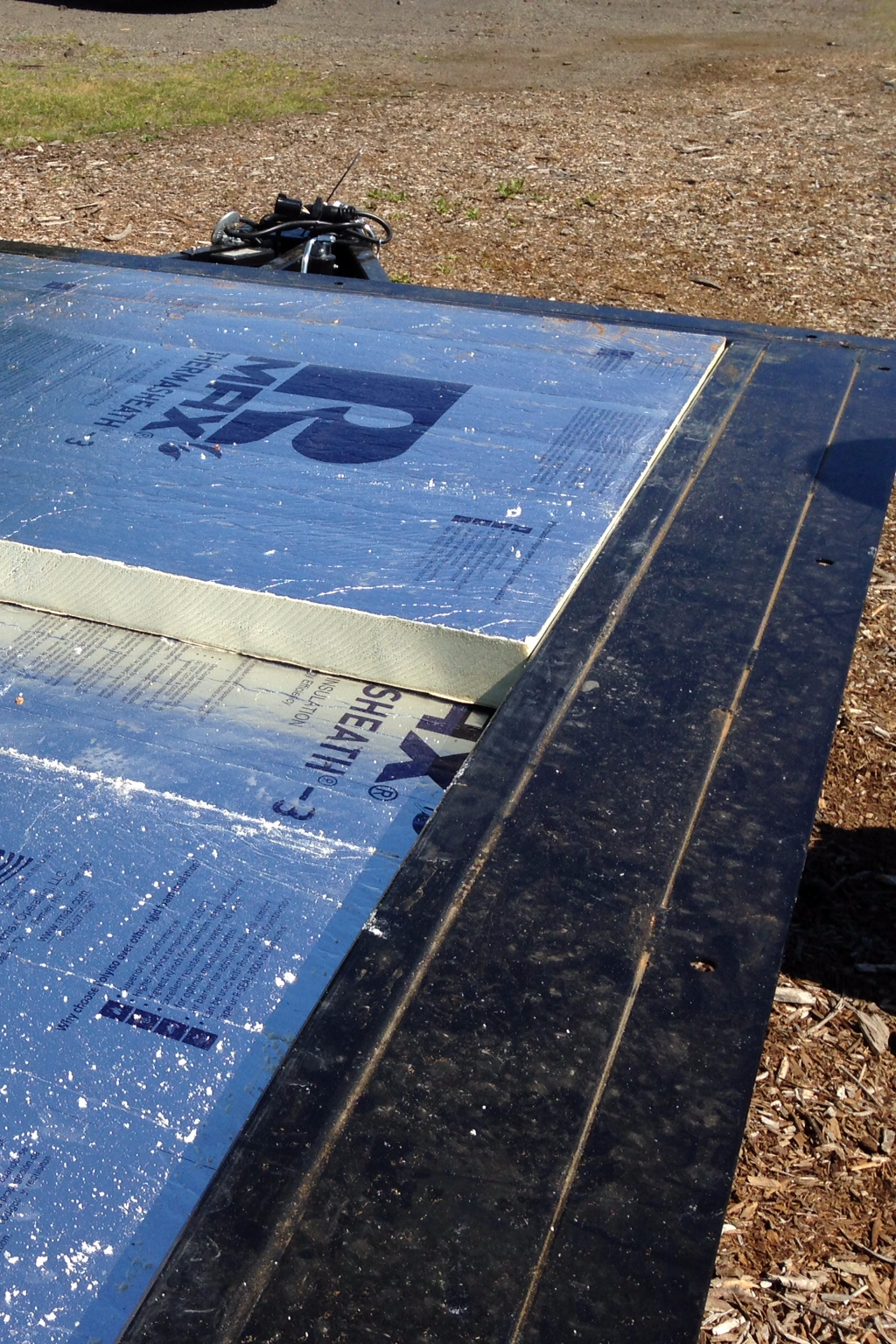

Andy and Tony helped me finish the last of the panel prep (painting the last two panels with R-Guard and leveling the trailer first thing. Then we were joined by Patrick Sughrue of Artisan Tiny House and Derin Williams of Shelter Wise. Our first wall went up around 10 AM and we got it braced into place while we got our second panel up and secured to the first. With two panels in place we had a corner! The next panel had to be cut out for the wheelwell, so we used the template I'd made to jigsaw out the curve on both sides, then removed the foam with a foam cutter, and installed blocking in recess. The second panel went up very nicely, snugging up against the first and the third panel followed along. Patrick showed us a trick to use a bottlejack in the right spot on the trailer frame to get the panels squared up. By lunchtime we had two walls up so we took a break to eat a picnic overlooking the river.

After lunch we popped the third wall into place and the first panel of the fourth wall (which is our Puzzle Wall). We started prepping the next parts of our puzzle wall. My friends Katie and Elliot from the east coast and my new friend Christian from Seattle all arrived around 4pm. The infusion of extra energy was very welcome, but we soon found ourselves scratching our heads because once we put the next wall panel up the first panel of that wall was far from level and nothing we tried straightened it out again. We finally decided to call it a day and come back to it in the morning. We pulled the last panel down and set it on the trailer again.

Yesterday, with fresh minds and bodies, Patrick and Christian removed the staples in the spline that joined the two panels and we were able to ratchet strap the panel back down into place. The next panel went up just fine afterwards and the rest of the Puzzle Wall came together nicely until we reached the last panel, which was long by about 1/2". There was only 1/4" difference between the two long walls in length, but that 1/2" wasn't working. The only thing we could figure was the the bottom plates weren't completely square. We'd measured thrice and checked square in the corners when we installed the bottom plates, but we hadn't taken diagonals, so next time we definitely will! We deliberated about a variety of options before Patrick landed on the plan: pull the last panel back, cut 1/2" off the second-to-last panel, scoop out the foam, and then slip the two panels together again. It worked beautifully!

We'd earned our lunch, so we headed up to my favorite St. John's haunt, Proper Eats, to celebrate having 4 walls up! After lunch Michael (who is also building a tiny house at Green Anchors) helped us get our glulam in place at the top of the tall wall. Then Patrick talked us through the roof details before he headed out.

Andy, Christian and I got our first wall panel (the biggest and therefore heaviest) and were horrified to discover how far off it was from square. One of the things I love best about SIPs is how well the usually come together! So we had another round of brainstorming before Andy reminded me that messed with the level of the trailer the day before while trying to get those two Puzzle Wall panels to square up! Usually we level the trailer before we start raising walls and again before we install the roof. As soon as we leveled the trailer the roof panel lined up beautifully! I can't believe I forgot, but I don't think I'll ever forget again!

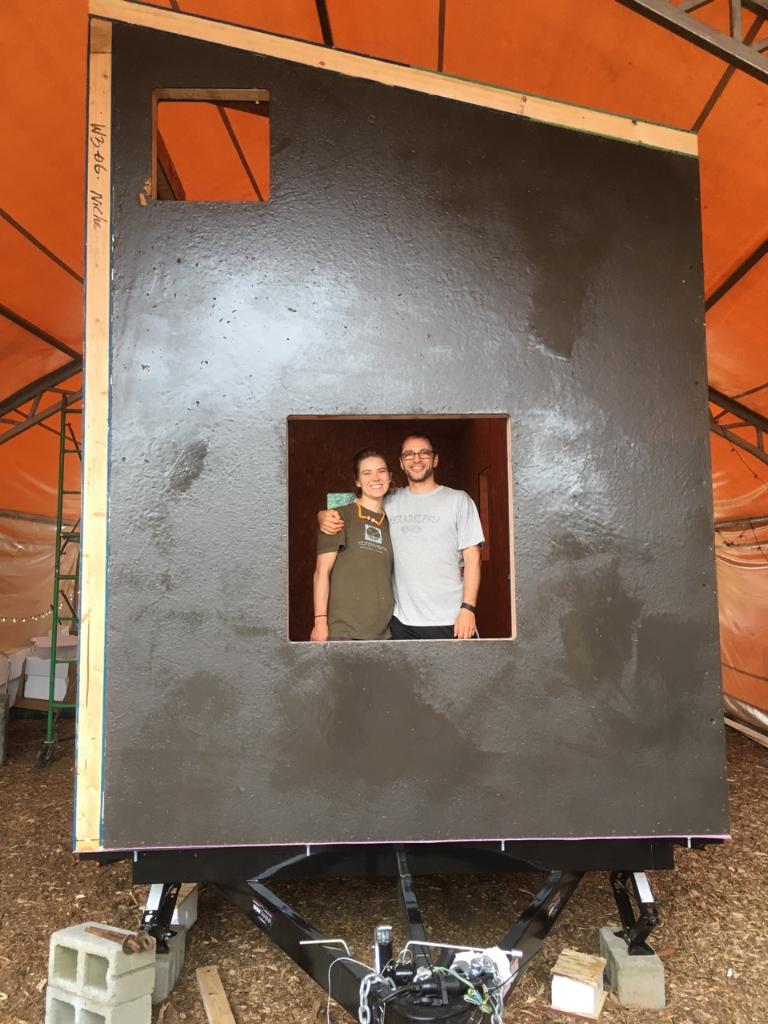

Isha came down after work as we were wrapping up and we got to enjoy stepping into our house with all four walls up (and a roof panel, too!) We celebrated with a beer at Occidental Brewing around the corner. Whew!

Today Andy, Kelly, and I will work on the roof raising. It's raining (of course!) so I'm really glad we're under shelter. Here we go!